Shop floor dynamics in the manufacturing space

For nearly a decade, Ravi has been working on the shop floor of a manufacturing plant which produces metal components for the automotive industry. While the plant has functioned smoothly, it faces challenges such as equipment breakdown, production inefficiencies and safety risks for workers who operate heavy machinery.

Fast forward to 2024 – the shop floor has undergone digital transformation. The company has integrated cutting-edge technologies such as digital twins, artificial intelligence (AI) and generative AI (GenAI) to enhance productivity and safety which has resulted in a highly efficient, sustainable and safe workplace. The workflow for Ravi is now seamless, with advanced technologies which enhance productivity and ensure the highest quality standards.

When it comes to manufacturing, shop floor is the meeting ground of design innovation and engineering on the one hand, and the production processes on the other. It serves as a crucible to assess the theoretical elements of design and engineering against real-world constraints and opportunities. However, despite the changes ushered in by industrial revolutions, companies are, at times, faced with a significant challenge – the shop floor remains a siloed space, disconnected from innovations led by the design and engineering teams, and insights from the marketing and sales functions.

Often, this disconnect results in inefficiencies and the products manufactured do not necessarily cater to market demands and client requirements, resulting in wasted resources. In such instances, efficient production gains priority over innovative and functional products, leading to compromises in product quality.

Further, lack of effective communication and a limited feedback loop could result in missed opportunities for iterative improvements, while the inability to adapt to changes in design and production processes on the shop floor could result in unnecessary delays and increased costs. Automation, which is often considered to be synonymous with Industry 4.0, may accelerate production. However, if the manufactured products are not aligned with market needs or do not meet the necessary quality standards, companies could be impacted by rising inventory costs and reduced profitability, and lag behind their competitors.

In this scenario, the Fifth Industrial Revolution spells hope and shop floors around the world have begun to perceive its transformative potential. Research indicates that asset-heavy industries such as manufacturing will see the fastest adoption of digital twins, and industrial internet of things (IIoT) will support this adoption,1 as their combined power can provide promising solutions to bridge some of the gaps that arise in a traditional shop floor setting. Hinging on the optimum leverage of human potential, Industry 5.0-enabled operational excellence can result in optimised operations, quality products, sustainability and employee satisfaction.

By providing a shared, real-time model of the production process and capturing real-time data from the shop floor, digital twins enable real-time monitoring and simulation, virtually replicating physical assets, processes or systems. By enhancing communication between different units – design, engineering and shop floor – it enables a smooth feedback loop for iterative improvements, while the simulated production scenarios help companies reduce waste and optimise resource allocation.

To add to that, predictive analytics provide actionable insights which result in informed decision-making. An analysis of historical and real-time data helps forecast demand, optimise production schedules and identify potential issues. There is also an option to explore design variations based on specified criteria which could lead to the development of more efficient, market driven, customer-centric products. All this combined contributes to safer, secure, sustainable and efficient work environments that are suitable for driving better business outcomes with people-power as its core.

Future-fit roadmap of Industry 5.0

For manufacturers, adoption of Industry 5.0 will enable them to build the resilience to deal with shocks, providing a healthy workplace for employees who have been increasingly anxious about job stability and security. Thus, developing the right roadmap for sustainability has now become a key priority for businesses.

To that end, the Fifth Industrial Revolution is a holistic advancement on Industry 4.0, a paradigm shift that adds collaborative solutions and adaptability to the smart technologies of the Fourth Industrial Revolution that enabled rapid and widespread automation of the shop floor.

While reinventing the shop floor, the focus of Industry 5.0 shifts from efficiency to creativity and ingenuity, and from mere automation to human-machine collaboration, carving out equal space for humans at the centre alongside machines. With the emphasis on the human component, change management becomes imperative to ensure that human-centricity, sustainability and circularity of the supply chain become the focal points of operations.

The change management imperative

A successful, holistic change management strategy can result in a satisfied, motivated and engaged workforce to drive productivity, while a sustainable environment can mitigate the risks of failure and resistance increasing the stickiness of change, fostering stability. When combined, they can enhance the resilience of a company. Grounded in these principles, Industry 5.0 entails the following four-pronged approach to be steered by employees and guided top-down by leaders with a robust mechanism to evaluate the benefits of the transition:

- Assess the impact of change on the shop floor

- Facilitate a shift in the workforce’s mindset to overcome resistance

- Unlock human capital’s potential with upskilling

- Redesign shop floor processes to drive innovation

Assess the impact of change on the shop floor

For seamless upskilling, employers must put to rest any fears employees may have regarding new technologies, boost their confidence and give them the tools and freedom to innovate. Job rotation programmes, instead of traditional training, would allow employees to experience diverse skill sets required for different roles.2 Simultaneously, it is important to define, manage and measure the impact that the changes associated with Industry 5.0 practices will have on the shop floor. These changes need to be assessed on parameters such as workforce behaviour, roles and responsibilities, processes and technology. It is also important to evaluate whether the workforce is ready to adapt to change and whether the organisation has the right support to make the transition smooth.

A case in point is an AI-powered assembly line in a manufacturing unit that has been using digital twins to identify and eliminate bottlenecks in real time – increasing output and decreasing production time.

Facilitate a shift in the workforce’s mindset to overcome resistance

To build a resilient mindset across the organisation, employers must identify the pain points and act on them. This would involve encouraging work-life balance, setting realistic expectations and transparent communication.3 Senior leaders need to assist middle managers to help build their own resilience and foster the same within their teams.4 The transformation needs to be assessed through an increase in employee satisfaction, not just productivity boost.

It is also important for leaders to identify the common reasons for resistance, such as scepticism about the benefits of change or fear of losing jobs due to automation. There could also be concerns about loss of autonomy. To increase buy-in, workers should be involved right from the planning stage. Open forums or one-on-one sessions may be required to ensure clear communication on how their roles and responsibilities will evolve.

As the new industrial equation reinforces the position of humans as central decision makers in a smart workspace, it is imperative to harness behaviours that encourage employees to get creative and be self-motivated. Equipping the workforce with tools that spark their ingenuity and allow them to collaborate with each other can drive productivity and efficiency.

For example, a car manufacturer has enabled people and robots to work side by side at future factories, while also creating a shared virtual space where engineers from around the world can log in to collaborate.

Unlock human capital’s potential with upskilling

With consumers becoming more vocal about social and environmental issues, companies are on the lookout for ethical skills. However, with limited time and resources, long reskilling and upskilling programmes are likely to make the employees weary and disengaged. Companies, therefore, need to adopt tailored approaches and facilitate upskilling in short courses in a gamified environment to enable a smooth and steady skill transfer.

In this context, a training needs assessment can enable businesses to identify workforce competency gaps. The assessment could focus on identifying the gaps between the current level of knowledge and skills on the shop floor and the desired level of knowledge and skills for Industry 5.0 technologies. The results can help identify key areas for upskilling as well as the educational methods that would be relevant to bridge these gaps.

The use of AI will also transform an Industry 5.0-enabled world. AI, which has three main uses today, assisted intelligence (GPS in a car), augmented intelligence (combination programmes that enable a service, like a ride-sharing app) and autonomous intelligence (machines acting on their own), could be used to create a world where human abilities are amplified as machines help mankind process, analyse and evaluate data.5

A case in point is PwC’s engagement in Europe where the team is working with a startup to create a new offering which uses augmented reality on factory shop floors. The offering aims to ensure quality assurance on the shop floor, upskill manufacturing workers and reduce cost of poor quality (COPQ).

Redesign shop floor processes to drive innovation

Manufacturers need to map current production processes to identify areas for integration of Industry 5.0 to drive productivity and innovation. Accordingly, they need to invest substantially in research and development (R&D) and foster a culture of innovation. Streamlined workflows, improved collaboration and new technologies could enable continuous improvement.

Breaking down silos between various functions can encourage brainstorming and problem-solving. Thus, workflows and processes should be restructured to promote agility, collaboration and flexibility. Some companies have already begun work in that direction.

Having adopted Industry 5.0 principles to drive innovation and flexibility in production lines, a company has developed technologies that are energy efficient and allow for precise customisation of machines to meet specific requirements, thus enabling the production of highly personalised products.

PwC’s change management framework

Effective change management strategies are essential for operational excellence, as they can help overcome employee resistance and foster a culture of continuous improvement. It is, therefore, crucial for business leaders to understand what motivates their shop floor workforce and train them in the key skills of Industry 5.0, which include:

Cognitive skills are rapidly growing in importance, which shows the increasing significance of complex problem-solving in the workplace.17 Emotional intelligence and critical thinking are important to develop the right prompts to fully leverage advanced technologies. Cognitive abilities also play a key role in interpreting and analysing data to make strategic decisions.PwC India’s change management strategy includes engagement activities, tailored communications and training support to engage, adopt and use.

Sustainable skills and practices will be at the heart of Industry 5.0 transformation. Employees can be trained on integrating IoT devices to monitor emissions in real time and leverage data analytics to optimise resource consumption. The workforce needs to stay updated on the latest environmental regulations and their implications. To make this process engaging, employers can highlight and reward innovative sustainable practices adopted by employees in their day-to-day life.

A smooth transition to Industry 5.0 will require expertise in AI/ML, knowledge of robotics and automation, and cyber physical systems, as well as data analytics. Combining digital twins with reinforcement learning, a branch of ML that lets a software learn through rewards and feedback, has been showing promise across sectors the world over.7 For example, by combining digital twins, simulations and reinforcement learning, autonomous vehicle manufacturers are able to simulate varied driving scenarios and weather conditions to identify risks and optimise efficiency of their algorithms and sensors, improving safety and driving behaviour.8

The transition to Industry 5.0 will entail more connected product and service value chains and will warrant pre-emptive and intelligent cybersecurity measures to safeguard the integrity of businesses, especially their manufacturing processes.9 While transitioning to Industry 5.0, organisations need to enhance overall cybersecurity controls; educating employees on both the basics (e.g. malware and phishing) and advanced topics of cyber security, such as AI regulations and ethics, IoT security, and data privacy will be equally important. The training could be tailored to specific job roles and can be done via workshops where potential attacks and defences are simulated.

In the case of a Gujarat-based manufacturer which embarked on a digital transformation journey, PwC India developed an effective change management strategy which started with identifying the formal and informal forces that were at play in the organisation.

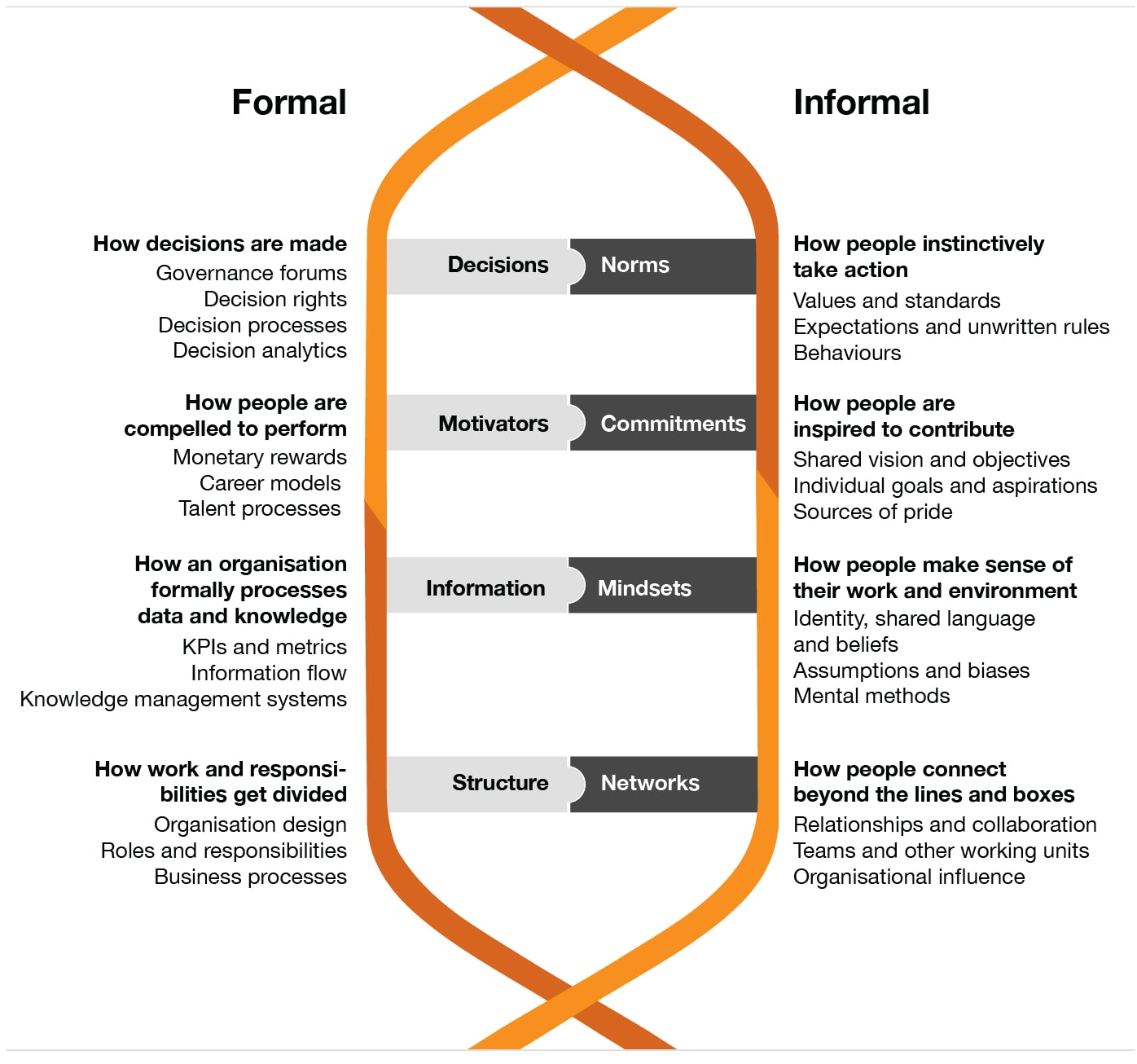

Assessment of formal and informal processes

As-is formal processes: The as-is state of formal functions was examined which included factors associated with the company’s decision making, such as the incentives it offers its high performers and the framework it uses to divide responsibilities.

Informal processes: To take stock of what drives employees, the informal people-centric processes of the organisation were assessed. This involved examining the unwritten rules and behaviours that lead people to act instinctively, understanding the motivations – like a shared vision and individual aspirations, which inspire workers to contribute, understanding the ways in which people connect to their workplace (shared languages and beliefs) and looking at how the relationships built in the workplace last outside of it.

The results of the assessment of formal and informal processes were combined with digital transformation to enable business growth and spur innovation opportunities, address market disruptions such as changing consumer preferences and adopt sustainable and regulatory standards.

Figure 1: Analysis of the as-is state of formal and informal

people-centric processes

Source: PwC analysis

Following this, programmes were curated to drive the four essential pillars for adoption of digital culture – skill, mindset, relationship and behaviour – by first setting and communicating clear and measurable goals.

The change management strategies and operations excellence initiatives were meant to:

- Achieve first mover advantage for the manufacturer.

- Build a happy workforce enabled by a digital and agile culture.

- Create a sustainable end-to-end digital value chain.

- Benchmark the level of digitisation with global manufacturing standards.

- Generate value through differentiated capabilities such as increased digital maturity score, data-driven and intelligent decision making.

Measuring change

In a span of a year-and-a-half, PwC India helped the company optimise its operations by:

- Enabling strategic decision-making and developing a smart factory.

- Setting a key performance indicator (KPI) baseline.

- Refining enterprise architecture and solutions.

- Integrating data analytics solutions.

The company saw 10% to 12% improvement in overall equipment effectiveness (OEE) over the baseline and up to INR 5 crore was saved in energy consumption costs. Besides, the freight cost came down by 3%, there was a reduction in safety incidents and a 15% improvement in on time in full (OTIF).10

The road ahead

The investment in Industry 5.0 technologies is, at present, fragmented and its adoption is not uniform across geographies or sectors. To keep manufacturers from running into regulatory hurdles, it is important for governments to form clear regulations on Industry 5.0 technologies and practices, while private players must make the best use of such policies and develop appropriate adoption roadmaps. As with any new technology, the adoption of Industry 5.0 is also likely to open up cyber vulnerabilities, especially as it operates on increased interconnectedness. Companies must adopt fool-proof data safety plans and train employees on cyber security.

Substantial investments are still required by the government and the private sector to make the adoption of Industry 5.0 a reality. For green manufacturing, a key tenet of Industry 5.0, manufacturers also have an opportunity to leverage government incentives such as the National Programme on High Efficiency Solar PV Modules11 and the Green Credit Programme.12 The former aims to reduce import dependence in the renewable energy sector and ramp up sourcing of local material in solar manufacturing13 while the latter incentivises voluntary environmental actions across diverse sectors.14 The long-term success of sustainability initiatives will depend on strong employee engagement and support. Companies which invest in a shared vision are likely to be gainers, as employees are prone to follow through when they copilot rather than merely execute the change.