Download the article

As medium-sized businesses seek to expand and grow, they encounter myriad challenges. Prahalad Chandrasekharan and Arun Raychaudhuri underline the top five challenges and propose potential solutions which can help these companies optimise productivity and achieve sustainable growth.

Did you know...

- India has the third largest number of medium-sized family-run businesses after the US and China.1

- There are, as of 2022, approximately 40,000 registered medium-sized enterprises in India.2

- The number of small enterprises that elevated themselves to the medium category increased by 75% from 3,699 in FY22 to 6,474 as of March 2023, signalling an important inflection point.3

- As many medium-sized firms strive to rise in terms of scale and growth, India may add 1,000 more companies to the list of large companies.4

- Most medium-sized enterprises in India are still run by families.

- Statistics reveal that 70% of family-run medium and small businesses fail before they can make it to the second generation and almost 90% don’t make it to the third generation.5 Reports indicate that 97% of them do not have family constitutions or succession planning documents.6

- In the next 15 years, 40% of India’s family businesses will undergo a handover from the founder to the second generation of owners, and 35% of them to the third or fourth generation.7

As is evident from the figures above, several small and mid-sized companies are at the cusp of transformation. Scaling up business will require these companies to articulate their goals, identify and eliminate business model constraints and strategically allocate resources.

It will also entail substantial investments in infrastructure and technology. However, this journey evidently is not without hurdles. Safeguarding the business against unexpected setbacks and establishing a strong market presence are as important as agile decision-making and professionalism to navigate the road to success.

This article highlights some of the challenges that medium-sized firms, operating in the range of around INR 250–500 crore revenue per annum, face and suggests solutions that can help them achieve the required scale and growth.

Growth imperatives

Most mid-sized companies require external investments to help build scale. Many of them have been considering the option of launching an initial public offering (IPO) to pare some of their equity and bring in investments. Garnering investments from equity markets requires them to have financial discipline, a sound operating model, reliable operations, good governance and professional management.

Besides, these organisations need to build a sturdy support system for sustainable growth as many of them have been formed by entrepreneurs from non-technical backgrounds who showed courage and tenacity to build their businesses from the ground up learning through trial and error. As the baton passes to the next generation – who are typically well-educated and eager to introduce more professional systems – there is a desire to ensure a smooth transition, adapt globally recognised best practices and build foundations for a sustainable growth.

PwC India has the experience of working with several mid-sized owner-driven firms, which are on the cusp of transitioning into more professionalised companies and has assisted them in their growth journey. Among other initiatives, PwC has helped tailor organisational practices to suit the unique organisational needs factoring in the firm's size, the skill level of its workforce, the aspirations of its stakeholders, and its constraints.

Entrepreneurs usually have a high degree of hunger for growth; however, often, they are not able to satiate the hunger due to poor reliability of operations. More often than not, there are enough opportunities, but companies are unable to leverage those due to poor performance delivery. An analysis of the problem reveals several interconnected factors at play such as:

- structure and accountability

- processes and digitisation

- people

- data and information

- sustainability

At the outset, manufacturing operations leaders should be able to introspect on their current approach and determine if it is enabling an accurate, centralised and fully connected view of its business ecosystem.

Following are five key questions that these organisations need to ask themselves before embarking on their growth journey:

Creating a well-defined roadmap to transition from local to global

The initiatives across the five dimensions discussed above are not one-time activities. These need to be evaluated at regular intervals and aligned to the changes in the business context. Companies should be able to dynamically adjust to the changes and should frequently assess the adequacy of the five dimensions.

This is where a neutral, unbiased perspective often provided in the form of assessment and backed by frameworks and insights of third parties, can come in handy. Often these frameworks are constantly amended as per the changing needs of the business.

The outcomes of such an assessment will either validate the leaders’ point of view or be an eye-opener to them and their teams. It can also provide significant room for improvement by bridging the gaps between current practices and best practices across maturity levels, paving the way to create a roadmap for improvement and growth, empowering client teams to plan and execute strategic actions with clarity and confidence.

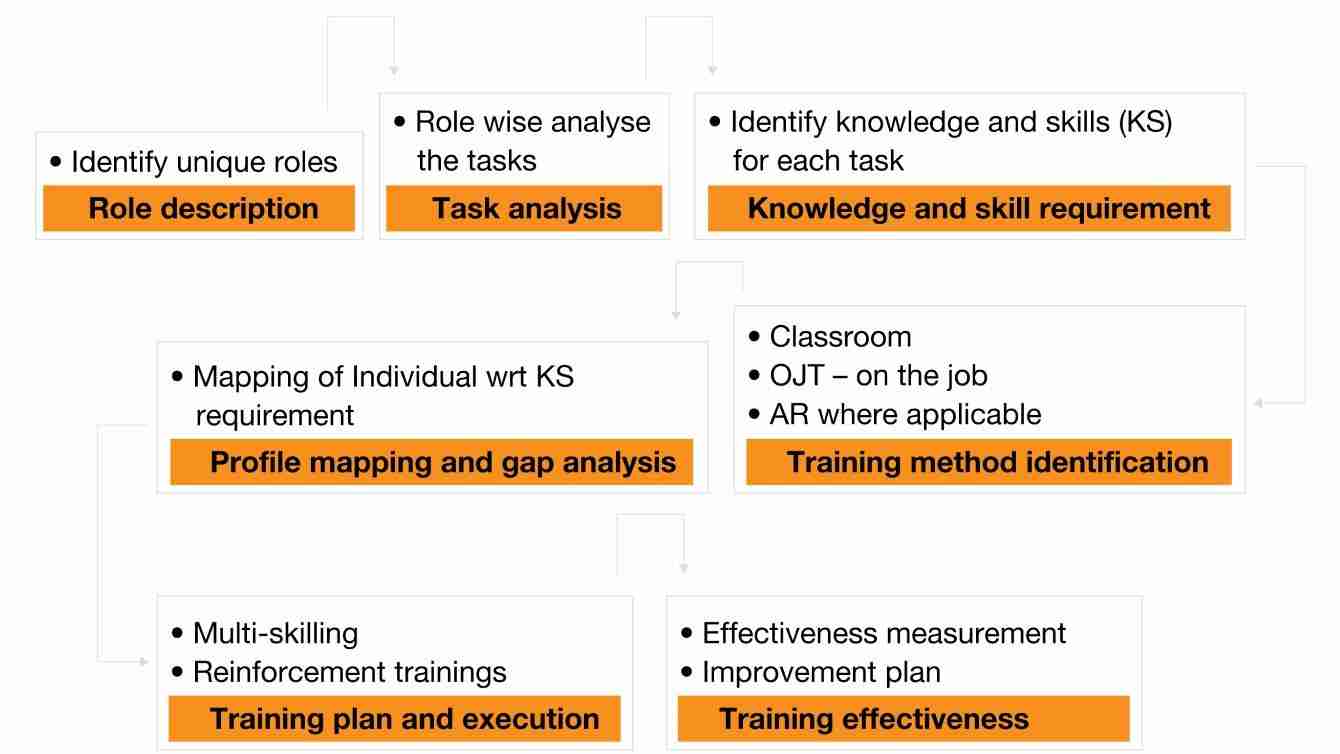

In order to derive true value from such endeavours, consultants on-site should tailor their approaches and solutions as per the individual client’s needs. The aim is not to deliver ready-made solutions but to foster an environment of continuous learning and development and ensure that the workforce is equipped with the necessary, up-to-date skills for success.

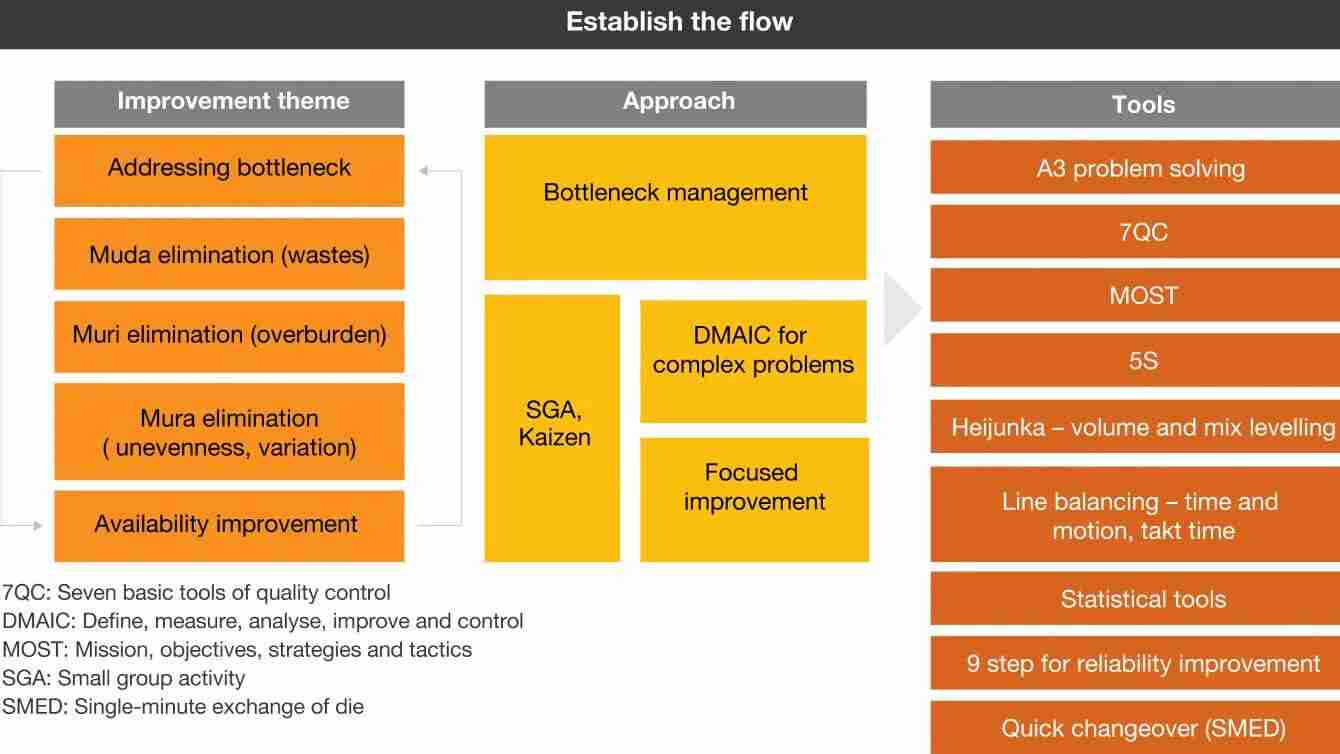

A robust operations management strategy can therefore act as a solid foundation that enables a firm to adapt, thrive and seize opportunities in today’s dynamic and fast-changing business landscape. Operations management also plays a vital role in risk mitigation as it equips a company with the aptitude necessary to anticipate and respond to potential disruptions and setbacks, ensuring business continuity. By optimising processes, streamlining workflows and enhancing resource allocation, companies can identify potential bottlenecks and inefficiencies and empower the organisation to make data-driven decisions and improvements swiftly.

Over the years, PwC India has taken on the role of actively assisting India's burgeoning businesses to prepare them for the global stage. The team at PwC India strives to bridge the operational gaps and unlock the potential within these organisations, enabling them to evolve from being successful domestic firms to becoming competitive global corporations.

Author introductions

Prahalad Chandrasekharan is Executive Director, Manufacturing and Operations Consulting

Arun Raychaudhuri is Executive Director, Manufacturing and Operations Consulting